For as long as human civilisation has practiced carpentry, we have used timber for packaging. These early days saw wooden boxes or crates as the solution for an individual or pair to move larger, heavier loads than they could on their own. Nothing has changed.

Wood remains a prominent material for transporting goods. However, the language seems to increasingly give new names to the essential wooden structure. At ABC Crates, we have heard customers refer to wooden transport crates as wooden boxes, export cases, timber cases, protective cases, plywood containers, the list is almost endless.

From pallets to crates, moulded custom shipping to containers for protecting wine, the world loves to move its products in wood. But why should your next shipment be protected by wooden packaging?

Durability

One of the best reasons to use wood over steel or plastic is wood’s durability in transit. Snow, sun, wind, rain, getting knocked, splashed with sea water or baked in deserts. In these conditions and more, steel would corrode or overheat products, plastic would crack or scratch, cardboard melts, warps or grows mould, but wood takes this abuse all while protecting your product.

Relatively Low Cost Compared to a Full Case

Wooden packaging, particularly standard crates and pallets, can be made from off-cut, cost-effective and reused timber stock. This provides businesses with a functional shipping option without denting margins.

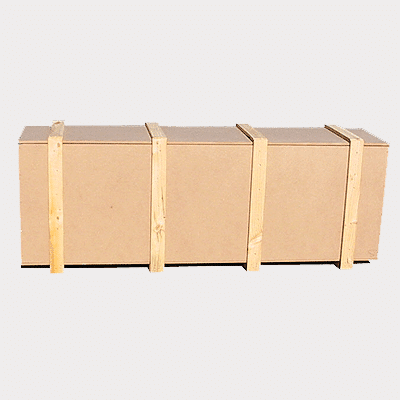

Weight (Much Lighter Than a Full Case)

Timber crates are designed to handle impacts, vertical weight while using less material than full wooden or plastic cases. Crates are made of the structurally significant planks of a case, without the extra weight of side and top boards. This leaves a rigid structure with much reduced packaging weight, saving your shipping rates.

Visibility of the Packed Product

The product inside a crate is readily visible. This means your goods are quickly identifiable, allows produce to breathe, and may even be showroom ready.

Stackable and Efficient Storage and Shipping

Thanks to our crate design, they are equal in strength to a full wooden case. The bracing and stacking requirements of a wooden crate ensure design is focused on strength in the structure. Steel is stronger, but is very heavy, cardboard lighter, but vulnerable to moisture, and has limited capacity for vertical pressure from stacking. Wooden, breathable and lightweight crates also offer an excellent solution to mid or long-term storage.

Eco-Friendly (Reusable and Recyclable)

Plastic, steel and even Medium Density Fibreboard (MDF) require energy and processing plants to create. Conversely, timber is as natural and renewable resource as available. Additionally, the longevity and natural resilience of wood means many crates can be used and reused for years. This increases the value of construction costs every trip.

The options for packaging and shipping materials are broad, but time and time again wood proves its versatility, affordability, ruggedness and versatility. If you are looking for a high quality, affordable option for shipping your product, call ABC Crates today, WA’s favourite supplier of wooden shipping solutions.

Related News

The Ultimate Guide to Choosing the Right Shipping Crate for Your Business

Choosing the right tools can make all the difference...

Keep Reading

Wooden Packaging v Plastic Packaging: What’s the Best to Use?

In the ongoing debate over wood v plastic packaging,...

Keep Reading

Sustainability in the Shipping and Packaging Industry – How Wooden Crates, Boxes, and Pallets are Making a Difference

In an era where environmental consciousness is paramount, industries...

Keep Reading

Enquire Today

Enquire Today