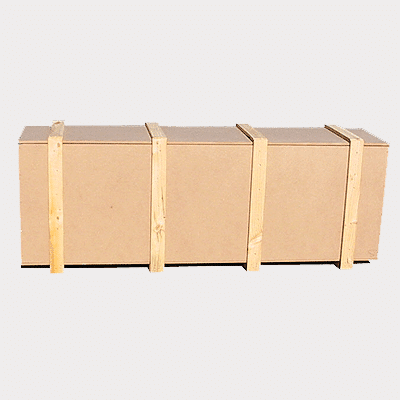

Export Pallets For Shipping

The reality of globalisation, international trade and the introduction of shipping containers means than nearly everything you eat, wear, play with, and give as gifts has at some point been strapped to a pallet and by plane, train or automobile been moved across the world.

If our experience of the world is so reliant on shipping, surely the first question we ask is: ‘How sustainable are our shipping practices?’

The key to most international freight is the humble pallet. It makes product easy to store, to load into a truck, and to move around a shop floor. But what is the best, and most sustainable, material to make export pallets out of?

Cost of Export Pallets

The first element to sustainability that few people talk about is cost. What does it cost the consumer, and what does it cost the earth?

Wooden pallets are often produced with the off cuts of commercial lumber production. Add to that the renewable source of wood, the low labour, production and material costs, and it is easy to understand that both the planet and your margins win with wooden pallets.

Financially, metal export pallets are by far the most expensive option, however long they last. Plastic export pallets are more expensive to manufacture than wooden pallets. Because they need to be made in a factory, the machinery, materials and labour to produce a plastic pallet is high. Get to know more about it here.

Export Pallets as The Greener Alternative

The manufacture and the disposal of export pallets that have the biggest implications on sustainability. Production of wooden pallets is quick, needing only a few nails and rough-cut wood. They can be made strong, treated for hygiene, repaired easily and last as long (or longer) than plastic equivalents. Conversely, moulded plastic export pallets producers have to consider oil extraction, refinement, shipping, plastic production, and moulding. Only then can they enter their useful life.

Possibly even more important is the end of a pallet’s life. No pallet is forever, and here the difference between wood, plastic and metal are most drastic. The reality of many export pallets is they wind up in landfill. Here, plastic and metal will last a long time without a hope of breaking down. Wood however, will decompose and leave little lasting impact.

If you wish to recycle, the topic many people don’t hear about is energy. Recycling metal and plastic pallets require an additional trip to the factory floors for melting, resetting and the energy production cycle starts all over again. That is a lot of electrical power to generate.

Wooden recycling often simply requires thirty minutes and a hammer to remove and reuse components that same day.

Longevity or Export Pallets

The final benefit of wooden pallets is the adaptability of the material. Because of the nature of the cutting, price, and how it is treated, wooden pallet planks are ready for innovative home designers to adapt into furniture, planter boxes, flooring or nearly endless other uses.

If you need Wooden boxes or export pallets for your business, and you want what is best for you and the environment, then wooden shipping material needs to be top on your list. C

all ABC crates for a quote on W.A.’s best manufacturer of wooden shipping crates materials today and let us help get your products across the world, sustainably.

Related News

Eco-Friendly Packaging Solutions: How ABC Crates is Leading the Way

When looking at packaging solutions today, one of the...

Keep Reading

The Ultimate Guide to Choosing the Right Shipping Crate for Your Business

Choosing the right tools can make all the difference...

Keep Reading

Wooden Packaging v Plastic Packaging: What’s the Best to Use?

In the ongoing debate over wood v plastic packaging,...

Keep Reading

Enquire Today

Enquire Today