When it comes to seamlessly incorporating wooden boxes into your manufacturing process, timing can be critical. The ideal time to consider export container design depends on the nature of your manufacturing process and the specific product you are producing.

Let’s discover the ideal time to consider wooden box design in manufacturing depending on the specific needs of your business and products – before, during, or after, and where to find top-quality transport boxes and crates from a reliable supplier.

Ordering wooden crates before manufacturing

For many businesses, the best time to order wooden boxes is in your product’s initial planning and design phase, as they can be customised to fit any unique specifications.

For anyone handling larger products or items with varying assembly times, it’s best to address wooden container design before any manufacturing. It’s important to treat the wooden crate as an integral part of the product rather than an afterthought, to ensure it seamlessly with the product.

In addition, if your product is regularly moved, handled, or staged during production, it may be more cost-effective to incorporate packaging into your process as a function of material handling. For example, wooden saddles from ABC Crates are made from quality, durable materials to make sure that all of your curved items can be transported from A to B without any potential damage.

Planning for wooden boxes during manufacturing

Manufacturers whose products are consistently produced can purchase wooden crates, boxes, and saddles in bulk during the production phase. By buying containers in bulk, businesses can save money and improve their bottom line, as well as help streamline the manufacturing process by providing efficient storage and transport solutions.

When ordering durable timber pallets and crates during the production phase, businesses can ensure that their products are transported and stored efficiently. This helps to reduce the risk of damage and improves the overall quality of the final product.

Export crate orders after manufacturing

For any business that develops customised products with varying designs to meet customer requirements, it’s best to address wooden crate design once the product is completed. This allows last-minute modifications that may be required, and it’s essential to ensure that the wooden boxes fit the final product perfectly – additionally, they can also enhance your brand image by providing a unique and sustainable packaging solution.

Depending on the size and complexity of the product, it may be more cost-effective to ship the product assembled in a single shipment, or disassembled with only a few ancillary packages. By considering these options and working closely with a renowned provider of timber pallets and timber packing, businesses can ensure that their products are delivered to the customer on time and in perfect condition.

Order reliable wooden boxes from ABC Crates

ABC is a Western Australian-owned and operated company that has been supplying high-quality wooden crates, cases, and pallets to a diverse range of customers since its establishment in 1995. With extensive experience in both product design and crate manufacturing, ABC is one of the most highly acclaimed manufacturers in Perth and the surrounding areas.

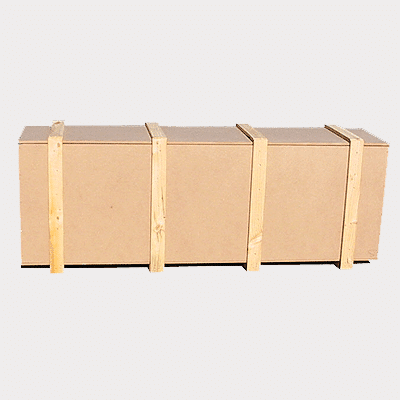

Our Wooden Crates, Wooden Pallets, Timber Packing, and Wooden Saddles products come in various sizes and styles, as well as custom designs, making it easy to transport goods of different sizes and weights. Browse ABC Crates’ range of superior wooden shipping and packaging products online now, or get in touch today with any queries.

Related News

The Ultimate Guide to Choosing the Right Shipping Crate for Your Business

Choosing the right tools can make all the difference...

Keep Reading

Wooden Packaging v Plastic Packaging: What’s the Best to Use?

In the ongoing debate over wood v plastic packaging,...

Keep Reading

Sustainability in the Shipping and Packaging Industry – How Wooden Crates, Boxes, and Pallets are Making a Difference

In an era where environmental consciousness is paramount, industries...

Keep Reading

Enquire Today

Enquire Today